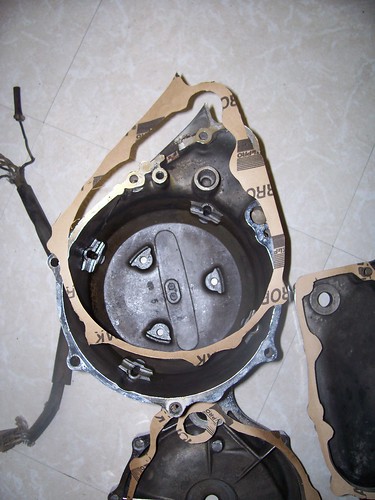

I did start drilling for the slugs. I know they need to be made, so might as well do it now.

The next one is a bit blurry, but you can see what I am doing.

This is the first time I have done this type of repair on a frame, so anyone that sees where I could go wrong with this let me know. I saw a post on chopperweb.info that showed using slits instead of holes to make shifting the slug around better. Of course that was after I drilled the holes.

I was concerned a bit about twisting so I drilled the holes at different distances 45 degrees from each other. Hope that no matter how it is twisted there would be something to help counter-balance the force.

Next thing I did was begin prepping for the tank mounts. I had originally thought about using the same style of mounts I had cut off the tank, but changed my mind and devised a new plan. Hopefully not an extremely stupid one. But a plan nonetheless.

1" flat stock drilled for bolts. I am going to weld the bolts onto this and clean it all up to be smooth. Before I do that, I need to get to work with a hammer to get a decent arc on the steel to follow the arc of the backbone tubing better. Then I will weld long bolts and cut them to length.

Then it will be welded into the the tunnel of the tank. After the edges and arc has been cleaned up.

Then I will use a strip of rubber to dampen the shakes and slide it down through the bar and I know where I can get some killer chrome spike nuts to tighten it all down.

And if I fuck it up. I guess I will fill it back up and then buy a sportster tank to get me by.