Some days you wake up with with the Midas touch and other days you wind up being Midas in a alternate reality.

You know, the one where you touch anything and it turns to shit.

A few things went on yesterday. I shifted the mount back for the seat it will be aligned better with the seatpan area of the frame and also welded in some lower bungs for the springs. They are a bit wider at the frame side than at the seat. But I did that to keep the frame looking clean (cleaner?) than it would if I have mounted them out in perfect alignment.

Now I did get a wild hair and tried to make my own seat springs out of those hand exercisers. Which if I was about 40 pounds lighter might have worked better. As it was my ass flattened them out with out any movement left. And the second problem was that both were wound the same. So with the offset mounts the springs were binding up and causing troubles. Not really a big deal, I spent four dollars on them and had figured if they didn't work it wouldn't break the bank. Now I will have to go and buy a proper set and get them installed.

I also tried to repair the studs on my girder yesterday. And fucked them up. I had found some hardware that would be direct replacement in size and thread pitch for what I had to remove. But I got the bore off center and when I tried to force an alignment, I wound up knocking it off even further. So now my happy ass will have to take the whole thing off and start it from scratch. It is salvageable though. Thankfully it is salvageable.

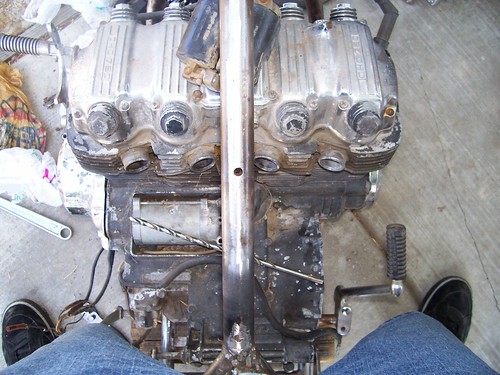

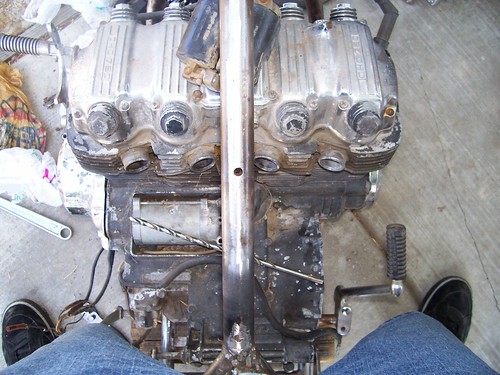

After the morning of fabrication disappointment, I hauled the frame over to where the motor is being stored.

The frame repairs came out sweet. All the mounts are lining up perfect, but I may have found the reason for the cracked rails. It appears that there is about 1/8" of gap from the mounts to the motor. And when I received the bike, the previous owner had just sucked up the gap.So they basically pre-stressed the frame. Now granted this may have taken years to accomplish, but I doubt that it was helpful to the situation.

Now the final round of irritation. I had asked about something I had seen on the front of the engine. Now I have taken cursory looks at the motor. Basically to see if it was turning, had compression and to check the shifting and trans operation. I had never flipped it over to inspect the underbelly. From a side glance it looked good. Well I began to flip it around to get a good and close inspection of the oilpan... What the hell?! No oil pan. So I need an oil pan for the bastard.

But I do have a nice oil cooler riser for the motor. Too bad I am guaranteed to not be able to keep any oil inside.

An interesting set up for the cooler. It is an aluminum riser with a pressure valve on the outlet half of the filter and came with a threaded nipple and a nut that acts like a coupler. I didn't find any markings on it though. So no idea who made this little fella.

I had no plans on using an oil cooler. Mainly because I don't want to buy the cooler so maybe I will do as I have done with other pieces I have not wanted, trade them for the things I do. Or even hock it off and use the proceeds to purchase what I need.

Right now the motor and frame are hanging out with each other. And I have some pics to figure out pipe placement and such.

But look at this...

Talk about some serious width. That is a lot of motor. And as I keep looking at the bike, it is gonna be LOW. Four inches is not a lot of ground clearance. Depending on how that translates to riding fun, I may up my wheel sizes.

And I doubt that I am gonna have enough room to go with a 4-1 exhaust, so I will probably build 4-2 and split them to each side.

I was worried that the pipes would get in the way of the forwards. Now that I mounted a side to it, I realize I am gonna have enough space to route it under them.

Today if I have time after the Sunday chores I am going to take the tins down and fit them and get a few more pics of the bike and get a better idea on how it is going to look.